Product display

Complete oil equipment produced by our company, and realized from the raw material cleaning, squeeze, leaching, refined

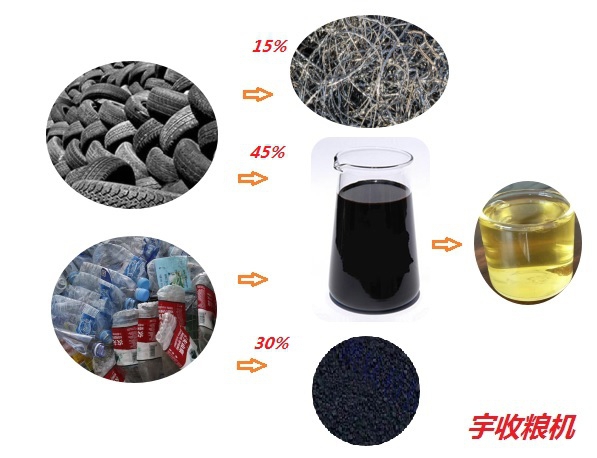

The waste tyre treatment industry is currently a state-supported environmental renovation project with low investment and high yield. The final products (fuel oil, carbon black and steel wire) have good marketing.

It consists of reactor, condenser, oil tank and so on. Users can produce qualified fuel oil only external circulating water after installing. The whole process is safe and environmentally friendly.

Splitting process of waste tyres:

The dismantled waste tyres are fed into the splitting furnace. The splitting furnace door is closed and the burner is fired to directly heat the splitting furnace. The oil-gas produced from the high tempture splitting process, flows into the oil storage tank through the condenser. The tail gas produced from the splitting is fed into the splitting furnace through the tail gas recovery system . The waste gas produced by combustion is discharged after the treatment of dust removal system.Till the splitting furnace is cooled, the side slag discharging door is opened, to collect carbon black,also take out inside iton wire .The whole process is over.

The obtained fuel oil can be further refined to diesel and gasoline.

Environmental Protection Treatment in Production

1. Waste air treatment

Tires and plastic splitting equipment eliminate waste gas pollution by installing water seals and tail gas recovery and combustion. Which not only eliminates exhaust gas pollution, but also saves a lot of fuel. In terms of smoke and dust emission, adding desulfurization and dust collector, the smoke and dust emission can reach the relevant standards of GB 13271-2001.

2. Waste water emission

Some weak acidic wastewater (about 50 kg wastewater per ton of oil produced) will be produced during the treatment of oil products from waste liquid plastic refining equipment. After neutral wastewater is neutralized by adding weakening liquor, the neutral wastewater is filtered through three stages to achieve harmlessness, and then discharged to a special evaporation processor (whose heat source is the flue waste heat of the main processor) to evaporate.

Basic parameters

Waste Tire Oil Extraction Equipment: 5-100T/D

Material application: waste tires, plastic products, etc

WeChat QR code

WeChat QR code

Company address:Room 302,Annexed West of H Building,No 76,Songxing Road (W),Baoshan District ,Shanghai

Factory address 1: Shanan industrial Zero, shenqiu county, Henan province

Factory address 2: No. 20, Guanliuzhuang Steel Market, Chengguan Township, Xinzheng City, Zhengzhou City, Henan Province

WhatsApp/Wechat/Mobile:+86 15560190216

http:// www.en-yusou.com

E-mail:teddy1556019@gmail.com