Product display

Complete oil equipment produced by our company, and realized from the raw material cleaning, squeeze, leaching, refined

The decolorization system of oil refining process, which is used to fully remove pigments from oil, such as carotene, chlorophyll and so on. At the same time, residual phospholipids, metal ions and oxides can be removed.

Basic process: use heating, vacuum to remove moisture from oil. The clay is sucked into the decolorizing pot by vacuum, then the clay is filtered out by vibrating filter after stirring, so as to change the color of grease.

Deodorizer Pot

It is used for decolorization of intermittent grease. It is suitable for decolorization of small tonnage oil products, generally not more than 30t / d. Alkali water washing oil was dehydrated and decolorized in decolorizing tank.

The pot body is a closed cylinder container with plate top cover and conical bottom. The pot is equipped with mixing device and heating coil, and the power motor is installed on the top cover. In addition, there are decolorizing agent inlet pipe, vacuum tube, oil pipe in and out, cooling pipe and so on.

The mixing device adopts mechanical stirring, that is, motor, reducer, coupling, mechanical seal, stirring shaft, stirring wing, bottom bearing and so on.

Type and data

type | TSG-120 | TSG-160 | TSG-180 | TSG-200 | TSG-220 |

capcity(T/Batch) | 1.5 | 3 | 5 | 8 | 10 |

cylindar(mm) | 1200 | 1600 | 1800 | 2000 | 2200 |

volume(m3) | 3.2 | 4.5 | 8.1 | 12.5 | 15 |

power(kw) | 2.2 | 3 | 4 | 5.5 | 5.5 |

heating area(m2) | 4.5 | 6.9 | 10 | 15 | 18 |

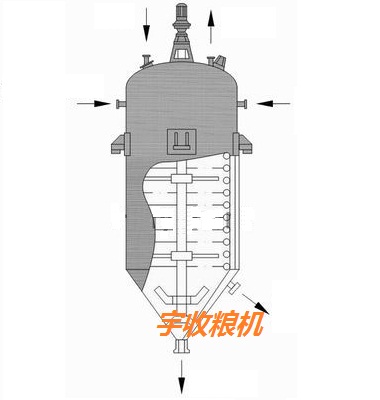

Bleaching Tower

It is used for continuous oil decolorization with large treatment capacity and less clay consumption.

It is used for continuous oil decolorization with large treatment capacity and less clay consumption.

The inner plate is divided into three layers to help the direct steam pipe to stir and avoid oil short circuit, and it is convenient to maintain the layer in and out of the layer. the bottom layer is equipped with indirect steam pipe for heating and heat preservation, because the decolorizing tower works in vacuum state, in order to avoid oil being pumped away by vacuum, there is an oil retaining plate at the top of the tower.

Compared with the traditional mechanical stirring decolorization tower, this machine has obvious advantages, the sealing performance of the whole equipment is good, there is no power consumption, the stirring is uniform, and the efficiency is high.

type and data

type | capacity (t/d) | cylindar (mm) | work temp (℃) | vacuum (MPa) |

TST80 | 20~30 | Φ800 | ≤120 | ≤0.096 |

TST100 | 50~80 | φ1000 | ≤120 | ≤0.096 |

TST120 | 90~120 | φ1200 | ≤120 | ≤0.096 |

TST160 | 180~250 | φ1600 | ≤120 | ≤0.096 |

TST200 | 350~460 | φ2000 | ≤120 | ≤0.096 |

TST240 | 500~670 | φ2400 | ≤120 | ≤0.096 |

TST280 | 800~1000 | φ2800 | ≤120 | ≤0.096 |

WeChat QR code

WeChat QR code

Company address:Room 302,Annexed West of H Building,No 76,Songxing Road (W),Baoshan District ,Shanghai

Factory address 1: Shanan industrial Zero, shenqiu county, Henan province

Factory address 2: No. 20, Guanliuzhuang Steel Market, Chengguan Township, Xinzheng City, Zhengzhou City, Henan Province

WhatsApp/Wechat/Mobile:+86 15560190216

http:// www.en-yusou.com

E-mail:teddy1556019@gmail.com